Technical Articles

Motors operate under continuous stress during regular use and maintenance activities. Without proper protection measures, they are vulnerable to excessive damage, which can significantly reduce their lifespan and efficiency. Developing possible risks and implementing appropriate protection devices at an early stage helps avoid unplanned outages and the associated repair costs. Various technologies and motor protection devices are essential in ensuring that they become reliable and efficient in numerous applications within industries and commercial premises.

This blog explores the key problems motors face, the importance of using reliable devices for motor protection, and how to choose the right components.

AC Motors consume almost 70% of industrial power. While DC motors allow for precise speed control, AC motors dominate the industry due to the easy availability of AC power. With the advent of Variable Frequency Drives (VFDs), AC motors now offer efficient, flexible speed control, further minimizing the use of DC motors in many applications.

Given their critical role in industrial operations, knowing how to protect them is essential for ensuring reliability and long-term performance.

Motors can break down for many reasons, often because of electrical or mechanical problems. If these problems aren’t fixed in time, they can cause the motor to overheat, damage its insulation, and eventually result in irreversible failure.

Excessive current generates intense heat. This can melt the motor's windings and burn the crucial insulation that protects them. Insulation materials are classified based on their tolerance to temperature, as defined by the IEC 60085 standard.

Class of Insulation

Maximum Attainable Temperature

°C as per IEC 60085

Y

90

A

105

E

120

B

130

F

155

H

180

C

>180

Traditionally, motors were built with Class ‘B’ insulation. Today, many modern motors use Class ‘F’ insulation for added safety. However, they are often designed to operate within Class ‘B’ temperature limits to maximize reliability and extend service life

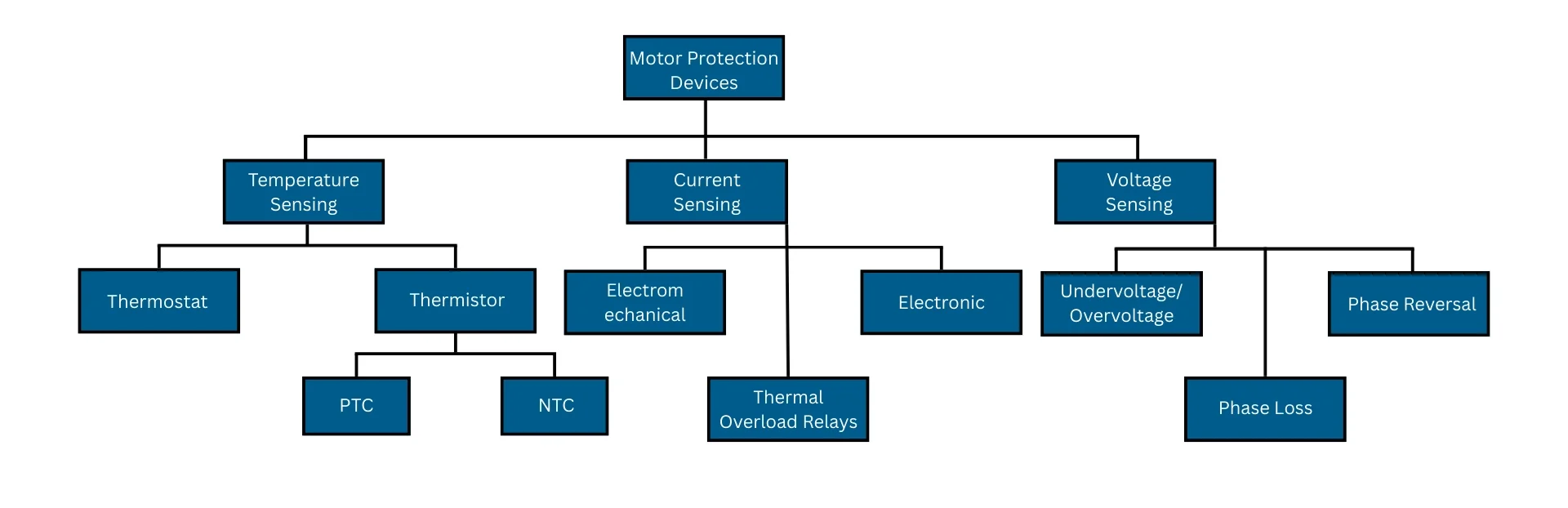

There are three main philosophies for protecting a motor:

Here are the common devices, categorized by the protection philosophy they use:

a) Thermostat: A simple temperature-operated switch that trips the power supply when a set temperature is reached.

b) Thermistor: A resistor whose resistance changes significantly with temperature. PTC (Positive Temperature Coefficient) thermistors are embedded in the motor windings during manufacturing. A control unit reads their signal and trips the motor if the temperature gets too high.

a) Electro-mechanical Overcurrent Relay: Operates using magnetic or mechanical force when the circuit current exceeds a preset value.

b) Thermal Overload Relay: Uses a bimetallic strip made of two different metals with different thermal expansion rates. As current heats the strip, it bends and actuates a tripping mechanism.

c) Fuses and Circuit Breakers (MCBs/MCCBs): These devices are crucial for short-circuit protection. They react instantly to the extremely high currents of a short circuit, disconnecting the motor in milliseconds to prevent catastrophic failure, fire, and damage to other components.

d) Electronic/Numerical Motor Protection Relay: A microprocessor-based relay that monitors current, voltage, temperature, and other motor parameters to provide accurate and flexible protection.

a) Undervoltage/Overvoltage Relays: This relay operates when the feeder voltage drops below or exceeds a set threshold, protecting the motor from harmful voltage fluctuations.

b) Phase Loss Relays: Detects the loss of one of the three phases (due to an open circuit, blown fuse, etc.). Since a motor running on two phases (single-phasing) overheats very quickly, this relay should trip the motor immediately.

c) Phase Reversal Relays: Checks the phase sequence of the power supply. It trips or blocks the motor from starting if the sequence is wrong, which is critical for equipment like pumps, compressors, and conveyors where direction of rotation is important.

With several options on the market, choosing the right solution depends on various factors. Here are some practical tips:

Overloads, short circuits, and phase failures are common causes of motor damage. Protecting motors against such occurrences is necessary to prevent operational losses and costly breakdowns. The right protection not only helps prevent failures but also ensures the motor's long-term efficiency and performance.

At Lauritz Knudsen Electrical & Automation, we have a comprehensive range of motor protection products, including protection relays, submersible pump motor starters, and other essential devices. Backed by decades of trusted expertise and product quality, we empower every customer with knowledge, reliability, and nationwide support to enhance operational performance and reduce downtime.

Explore our motor protection solutions today and connect with our experts to get started.

Quick Links

Miniature Circuit Breaker | Air Circuit Breaker | Home Automation Systems | Switches and Sockets | Variable Frequency Drives | Energy Management System | IEC 61439 Panels | Moulded Case Circuit Breakers | AC DRIVE | Submersible Pump Motor Starter | Mobile Starter | Industrial Automation | Residual Current Circuit breaker | APFC controller | Power Factor Correction | Motor Protection Device | Medium Voltage | Vacuum Circuit Breaker | Programmable Logic Controllers | Human Machine Interface | Solar MCCB

Assistance Required?

Select an option to Contact Us